Grease pumps are essential tools in industrial and automotive maintenance, ensuring that machinery operates smoothly by delivering consistent lubrication. Proper maintenance of a grease pump not only prolongs its life but also enhances the performance of the equipment it services. Neglecting routine care can lead to inefficiency, equipment damage, and unexpected downtime. This article provides practical tips and strategies for maintaining your grease pump effectively.

Understanding Your Grease Pump

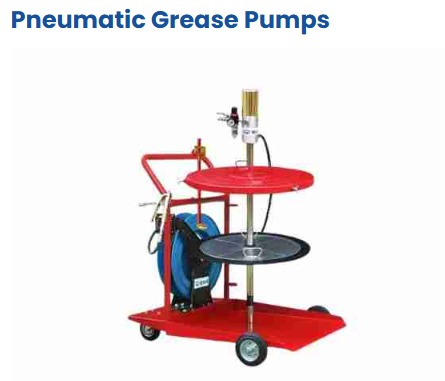

A grease pump is designed to deliver lubricants such as grease to specific points in machinery, ensuring smooth operation and reducing wear. These pumps are commonly found in automotive garages, manufacturing plants, and heavy-duty machinery maintenance setups. Knowing the components of your grease pump is the first step toward effective maintenance.

Typical grease pumps consist of the following parts:

- Pump body: The main housing that contains internal components.

- Plunger or piston: Responsible for pushing grease through the outlet.

- Reservoir: Stores the grease to be dispensed.

- Hoses and fittings: Channels that guide the grease to specific lubrication points.

- Control valves or triggers: Help regulate the flow of grease.

Familiarizing yourself with these parts allows you to identify potential issues early and perform targeted maintenance.

Daily Maintenance Practices

Maintaining a grease pump starts with daily attention. Daily maintenance helps prevent blockages, leakage, and other operational problems. Key daily practices include:

- Inspecting for leaks: Check hoses, fittings, and the pump body for signs of leakage. Grease leaks can reduce the efficiency of the pump and create a mess in the workspace.

- Cleaning the exterior: Wipe down the pump after each use to prevent grease buildup. This helps maintain smooth operation and prevents contamination of the lubricant.

- Checking grease levels: Ensure the reservoir is adequately filled with the correct type of grease. Operating a pump with low grease can damage the plunger and lead to inconsistent flow.

Regular daily inspections reduce the likelihood of larger, costly repairs and keep the grease pump in optimal working condition.

Proper Lubricant Handling

The longevity of a grease pump heavily depends on the quality and handling of the lubricant used. Always use the recommended type of grease for your specific pump model. Different pumps are designed for different viscosities, and using the wrong type can result in clogs or internal wear.

Other tips include:

- Store grease properly: Keep grease containers sealed and in a cool, dry place to prevent contamination.

- Avoid mixing greases: Mixing different types of grease can lead to chemical reactions that affect lubrication quality.

- Use clean tools: Ensure that any tools used to handle grease are clean to avoid introducing dirt or debris into the pump.

Proper lubricant handling ensures smooth flow, reduces internal wear, and maintains the efficiency of your grease pump over time.

Routine Inspection and Component Checks

To maximize performance, it’s crucial to conduct regular inspections of all grease pump components. These inspections can identify wear and tear before it leads to pump failure.

Focus on the following areas:

- Hoses and fittings: Look for cracks, kinks, or signs of wear that could affect grease delivery. Replace damaged parts immediately.

- Plunger and seals: Check for signs of wear or leakage. Worn seals can cause the pump to lose pressure and reduce lubrication efficiency.

- Reservoir condition: Inspect the reservoir for contamination, such as dirt or metal particles, which can degrade the performance of the pump.

Performing these checks on a weekly or monthly basis, depending on usage frequency, can dramatically extend the service life of your grease pump.

Preventive Maintenance Techniques

Beyond inspections, preventive maintenance helps avoid breakdowns and ensures consistent pump performance.

- Regular lubrication of the pump itself: Some grease pumps require lubrication of moving parts like the piston or plunger. Consult your pump’s manual for guidance.

- Flush the system periodically: Over time, old grease can harden and cause blockages. Flushing the pump with compatible solvent or cleaner removes buildup and maintains flow.

- Replace worn components proactively: Don’t wait for parts to fail completely. Replacing hoses, seals, and gaskets before they break reduces downtime and keeps the pump reliable.

Implementing a preventive maintenance schedule ensures that your grease pump operates efficiently and reliably for years.

Operational Best Practices

How a grease pump is used daily impacts its longevity as much as maintenance practices. Proper operation can prevent premature wear and maintain consistent performance.

Consider these best practices:

- Avoid over-pressurizing: Excessive pressure can damage internal components. Use the pump within the recommended pressure range.

- Operate smoothly: Avoid rapid pumping or forcing the trigger, which can strain the mechanism.

- Use compatible accessories: Ensure that hoses, fittings, and couplers are compatible with your grease pump model. Incorrect accessories can lead to leaks or poor performance.

Training staff or operators on correct pump usage also reduces the risk of human error and prolongs the life of the pump.

Troubleshooting Common Issues

Even with proper maintenance, grease pumps can encounter issues. Quick troubleshooting helps minimize downtime.

Common problems include:

- Reduced grease flow: Often caused by air in the line, clogged hoses, or low reservoir levels. Bleeding the pump and checking for blockages usually resolves this.

- Leaking grease: Inspect seals, hoses, and fittings for damage. Replacing worn seals or tightening fittings often fixes the problem.

- Pump not priming: This can occur if the pump is dry or the plunger is worn. Prime the pump according to the manufacturer’s instructions or replace the plunger if necessary.

Addressing these issues promptly keeps operations smooth and prevents minor problems from becoming major failures.

Storing Your Grease Pump

When not in use, proper storage is essential. Store the pump in a clean, dry environment to avoid corrosion and contamination. Covering the pump protects it from dust and moisture. If the pump will be idle for a long period, drain the grease from hoses to prevent hardening and clogging.

Regularly checking the stored pump before use ensures it is ready for immediate operation and avoids unexpected breakdowns.

Conclusion

Maintaining a grease pump is vital for ensuring the longevity and performance of your lubrication system. By following daily maintenance routines, handling grease properly, conducting regular inspections, implementing preventive maintenance, and adopting operational best practices, you can maximize efficiency and minimize downtime. A well-maintained grease pump not only saves costs on repairs and replacements but also ensures that machinery operates smoothly, safely, and reliably. Investing time and attention into your grease pump today guarantees optimal performance for years to come.